We are proud to announce that NeoCast is now in a position to supply you with a set of magnesium alloy headforms (all standard sizes available, see Fig. 1) that fully comply with all the requirements of the current EN960:2006 standard in terms of shape, precision-balanced centre of gravity and high resonance frequency. The optimal properties of our headforms are the fruit of a major research commitment and the use of new technologies throughout the entire production cycle. In the design stage, we use state-of-the-art CAD programs to create digital schematics enabling us to include all the technical parameters to be taken into account in the production of the desired headforms.

We are proud to announce that NeoCast is now in a position to supply you with a set of magnesium alloy headforms (all standard sizes available, see Fig. 1) that fully comply with all the requirements of the current EN960:2006 standard in terms of shape, precision-balanced centre of gravity and high resonance frequency. The optimal properties of our headforms are the fruit of a major research commitment and the use of new technologies throughout the entire production cycle. In the design stage, we use state-of-the-art CAD programs to create digital schematics enabling us to include all the technical parameters to be taken into account in the production of the desired headforms.

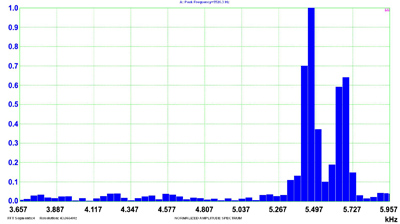

This computer-aided design is then used by the digital machine tools to create the actual casting model. One of the essential measurement factors of all the models we design is the headform’s resonance frequency that, according to the provisions of the current standard, should be no lower than 2 kHz. The additional thermal treatment stage included in the production process – technology developed by our company – enables us to obtain models with a resonance frequency almost twice as high as the minimum threshold laid down in the standard (Fig. 2). A further major advantage offered by the set is the acceleration sensor attachment base, developed in association with the Polish Central Institute for Labour Protection. This collaborative work enabled us to produce a system that leaves the test results unaffected by the resonance specific to the base/sensor set-up. Finally, the aesthetic qualities of the model are obtained by subjecting it to a two-stage coating process designed to protect the headform from external conditions. While we naturally remain at your entire disposal should you require further details, we would like to emphasize that, since its creation in 2005, the NeoCast company has concentrated its expertise on manufacturing casts that fully satisfy its customers’ highest requirements in terms of resistance and usability.

Fig. 2. Distribution of the headform resonance frequency

Our enduring ambition, and the goal of all our activities, is to provide our clients with the solutions they need to compete in present-day market conditions and to fulfil orders in a prompt and cost-effective manner. Thanks to the application of cutting-edge technological solutions in our foundry (we work closely with fundamental research and development facilities in Poland), we do our very best to provide casts that are both competitively priced and engineered to meet the customer’s specifications. By concentrating on the needs of our client companies and drawing on the experience and expertise of our employees, we can dynamically adapt to the ever-changing market demand for aluminium, magnesium, copper and zinc alloy casts.

Features :

- Material: Magnesium K1A allow

- 100% CNC machined casting patterns

- Single-piece construction (precison casting) - very durable

- Complies with EN960 and EN960:2006 requirements

- Resonance frequency > 2kHz

- Only one accelerometer is needed to fit into a complete set of headforms

- Single attachment cone is needed to fit into a complete set of headforms

- Aesthetic finish

- All sizes available

Click here to download more information about head forms !

CNC machining magnesium-casting of the head form