NeoCast is a company in the development and supply of high quality extruded products. We offer a full range of extruded magnesium alloys and we also continue to develop new alloys, metal matrix composites for future applications. NeoCast produces extruded magnesium alloys to a variety of specifications and customer requirements. Magnesium extrusions are typically specified by the EN standard. This spec defines chemical specifications, minimum mechanical properties and dimensional tolerances for an extruded magnesium product. All extruded profiles are considered. We can help bring your idea to reality.

NeoCast is a company in the development and supply of high quality extruded products. We offer a full range of extruded magnesium alloys and we also continue to develop new alloys, metal matrix composites for future applications. NeoCast produces extruded magnesium alloys to a variety of specifications and customer requirements. Magnesium extrusions are typically specified by the EN standard. This spec defines chemical specifications, minimum mechanical properties and dimensional tolerances for an extruded magnesium product. All extruded profiles are considered. We can help bring your idea to reality.

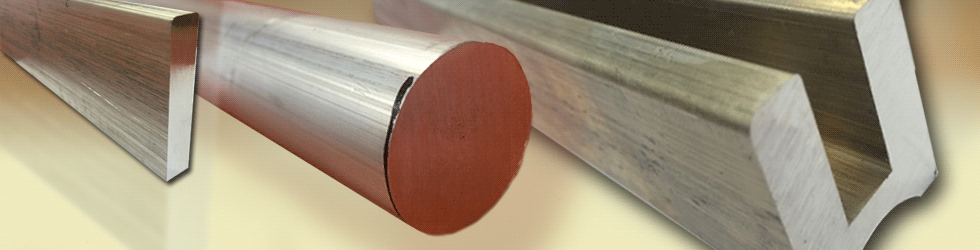

Continuous cast ingots:

- round bar: 70mm, 100mm, 150mm, 170mm, 190mm, 250mm, 300mm. Maximum length up to 2000mm;

- rectangular bar: 300x150mm. Maximum length up to 2000mm;

- other possible to customers specification;

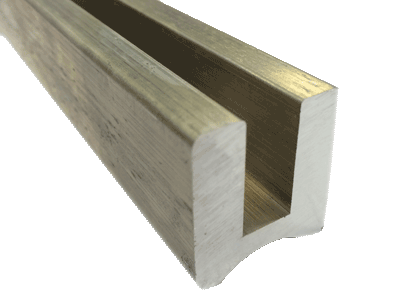

Hot extruded shape profiles (Maximum length 3000mm):

- tubes: Ø22x2.5mm, Ø25x2.5mm, Ø28x4mm, Ø28x3mm, Ø28x2mm, Ø30x2mm, Ø30x4mm, Ø35x2.5mm, Ø35x3.5mm, Ø36x3mm;

- square: 32x32x3mm, 40x40x7mm;

- rods: Ø7mm, Ø10mm, Ø12mm, Ø14mm, Ø15mm, Ø16mm, Ø18mm, Ø19mm, Ø20mm, Ø21mm, Ø22mm, Ø25mm, Ø26mm, Ø28mm, Ø30mm, Ø32mm, Ø35mm, Ø40mm, Ø42mm, Ø45mm, Ø50mm;

- square rods: 9.8x9.8mm, 12x12mm, 15x15mm, 20x20mm, 32x32mm, 40x40mm;

-

rectangular rods: 22x20mm, 25x5.5mm, 30x15mm, 50x10mm, 50x28mm, 70x6mm, 80x5mm;

Extruded profiles are delivered in a variety standard tempers. These are summarized below:

- T1 - Cooled from an elevated temperature shaping process and naturally aged to a substantially stable condition;

- T4 - Solution heat treated, and naturally aged to a substantially stable condition;

- T5 - Cooled from an elevated temperature shaping process then artificially aged;

- T6 - Solution heat treated then artificially aged.

Application of extruded profiles:

• Automotive

• Hardware

• Earth moving equipment

• Ordinance

• Sporting goods

• Industrial furnaces

• Construction

• Marine, railroads and aerospace

Main hot extruded magnesium alloys:

AZ61A - a medium strength alloy, useful for fairly complex shapes where strength is important and temperatures do not exceed 120˚C. Good corrosion resistance;

AZ31B - standard magnesium extrusion alloy, offering a good combination of medium strength (up to 120˚C) and corrosion resistance, coupled with good extrudability for more complex shapes;

AZ80 - strongest of the AZ alloy family, offering good strength at ambient or medium temperatures(up to 120˚C). Good corrosion resistance. Can also be forged for good properties;

ZK60 – high strength legacy alloy used in forging and machine from solid applications;