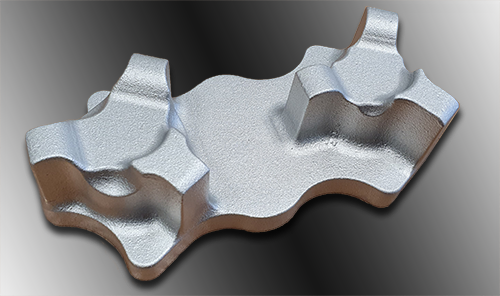

Magnesium casting

NeoCast - Light Metal Technologies is a magnesium foundry producing sand and permanent mold magnesium castings since 2005. We have 12 years of experience in the foundry business and our casting quality satisfies the most demanding automotive industry requirements. We are here to help you with any magnesium gravity casting needs.

NeoCast - Light Metal Technologies is a magnesium foundry producing sand and permanent mold magnesium castings since 2005. We have 12 years of experience in the foundry business and our casting quality satisfies the most demanding automotive industry requirements. We are here to help you with any magnesium gravity casting needs.

There have been numerous improvements to our facilities and operations in the past few years: new automatic sand system, new and improved sandmix machine, company wide training in all areas.

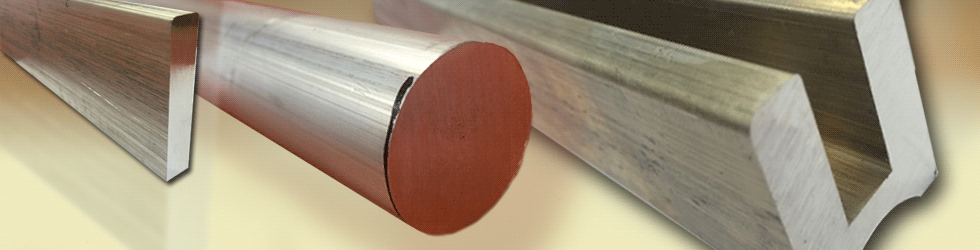

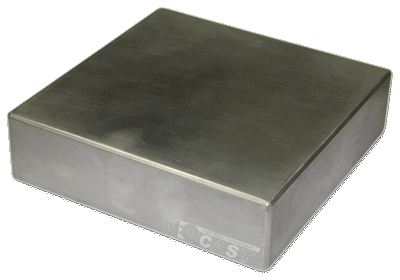

Magnesium billet and block for CNC machining

In our foundry we cast magnesium block then cut in the cuboid form of a size requested by the customer. Our specific expertise, experience and technological resources allow us to manufacture a single block up to 100kg of its weight. We offer forms of the following magnesium alloys: AZ91, AZ31, AM60, as a fixed range of products. Moreover, we provide blocks of other magnesium based alloys such as: RZ5, Elektron21, etc. We may pleasurably declare that we are currently the only one manufacturer of the magnesium billets located in East Europe (the material is produced in Poland and it is not imported from Far East).

In our foundry we cast magnesium block then cut in the cuboid form of a size requested by the customer. Our specific expertise, experience and technological resources allow us to manufacture a single block up to 100kg of its weight. We offer forms of the following magnesium alloys: AZ91, AZ31, AM60, as a fixed range of products. Moreover, we provide blocks of other magnesium based alloys such as: RZ5, Elektron21, etc. We may pleasurably declare that we are currently the only one manufacturer of the magnesium billets located in East Europe (the material is produced in Poland and it is not imported from Far East).

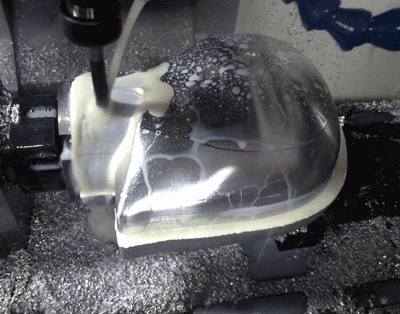

CNC machining of magnesium and aluminium alloys

Modern machinery park and many years of experience in the field of light metal processing (magnesium and aluminum) allows us to realize orders for many industries - i.e. automotive, aviation. As a reliable partner, we have been successfully cooperating with both domestic and foreign companies, continually increasing our capabilities and production capacities, adapting ourselves to the latest development trends and the needs of the automotive, window, casting. Using professional CAD / CAM and machine tools we can make non-standard parts with very complicated shapes according to the supplied technical documentation of the customer in very short time (rapid prototyping)

Modern machinery park and many years of experience in the field of light metal processing (magnesium and aluminum) allows us to realize orders for many industries - i.e. automotive, aviation. As a reliable partner, we have been successfully cooperating with both domestic and foreign companies, continually increasing our capabilities and production capacities, adapting ourselves to the latest development trends and the needs of the automotive, window, casting. Using professional CAD / CAM and machine tools we can make non-standard parts with very complicated shapes according to the supplied technical documentation of the customer in very short time (rapid prototyping)

Battery bridge cable

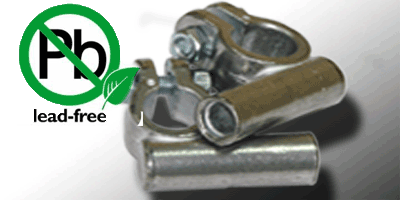

New product innovation! Eco-friendly, lead-free battery terminals (clamp) and battery cables

New product innovation! Eco-friendly, lead-free battery terminals (clamp) and battery cables

The NeoCast Company manufactures a range of universal battery clamps (terminal) designed for both cars and trucks. According to European Union regulations (ROHS 2002/95/WE) restricting the use of certain hazardous substances in electrical and electronic equipment, our products are entirely lead-free and consequently friendly both to people – and, notably, to the end-users who mount our products – and to the natural environment. It is worth mentioning that other alloys (e.g. brass) used to produce battery clamps contain lead as one of the basic alloy additives.

Plasma electrolytic oxidation of light metals (magnesium, aluminum)

Magnesium alloys are characterized by lower corrosion resistance, therefore, in some applications it is necessary to apply a protective layer against oxidation. With the available anti-corrosion coatings on magnesium alloys, plasma electrolytic oxidation achieves the best anti-corrosion effects as well as enhanced hardness and aesthetically appearance.

Magnesium alloys are characterized by lower corrosion resistance, therefore, in some applications it is necessary to apply a protective layer against oxidation. With the available anti-corrosion coatings on magnesium alloys, plasma electrolytic oxidation achieves the best anti-corrosion effects as well as enhanced hardness and aesthetically appearance.

Welding of Magnesium Alloys - TIG rods

NeoCast - Light Metal Technologies offer an extensive range of magnesium alloy welding rod for TIG (argon arc) welding. AZ92A is the most popular wire and produce superior joints with the maximum tensile strength offered by this alloy. AZ92A is Mg - 9 Al - 2 Zn welding alloy which finds wide use for fabricating and repair welding of many similar compositions. Casting repair and refurbishment is the most common application. AZ92A is preferred for joining many casting alloys.

NeoCast - Light Metal Technologies offer an extensive range of magnesium alloy welding rod for TIG (argon arc) welding. AZ92A is the most popular wire and produce superior joints with the maximum tensile strength offered by this alloy. AZ92A is Mg - 9 Al - 2 Zn welding alloy which finds wide use for fabricating and repair welding of many similar compositions. Casting repair and refurbishment is the most common application. AZ92A is preferred for joining many casting alloys.

Battery terminal to crimp

NeoCast company manufactures a range of universal battery clamps (terminal) designed for both cars and trucks. According to European Union regulations (ROHS 2002/95/WE) restricting the use of certain hazardous substances in electrical and electronic equipment, our products are entirely lead-free and consequently friendly both to people – and, notably, to the end-users who mount our products – and to the natural environment. It is worth mentioning that other alloys (e.g. brass) used to produce battery clamps contain lead as one of the basic alloy additives. The products manufactured by our company boast solid workmanship, high aesthetic qualities and possess outstanding mechanical properties (Rm>300MPa, A5>20%), providing them with a long, trouble-free useful life.

NeoCast company manufactures a range of universal battery clamps (terminal) designed for both cars and trucks. According to European Union regulations (ROHS 2002/95/WE) restricting the use of certain hazardous substances in electrical and electronic equipment, our products are entirely lead-free and consequently friendly both to people – and, notably, to the end-users who mount our products – and to the natural environment. It is worth mentioning that other alloys (e.g. brass) used to produce battery clamps contain lead as one of the basic alloy additives. The products manufactured by our company boast solid workmanship, high aesthetic qualities and possess outstanding mechanical properties (Rm>300MPa, A5>20%), providing them with a long, trouble-free useful life.

Magnesium anodes - AZ63

NeoCast's magnesium anodes are produced in a variety of shapes and sizes for use in seawater, brackish water, and fresh water cathodic protection systems. Our experience in producing galvanic anodes assures that you will receive top quality anodes that will effectively inhibit corrosion when used in a properly designed and maintained cathodic protection system. NeoCast's magnesium anodes conform in composition to the requirements of European Union standards. This 6% aluminum, 3% zinc alloy (AZ-63) usually provides the best combination of economy and operating characteristics in seawater or brackish water. For further information, or to discuss your specific requirements, contact our sales office.

NeoCast's magnesium anodes are produced in a variety of shapes and sizes for use in seawater, brackish water, and fresh water cathodic protection systems. Our experience in producing galvanic anodes assures that you will receive top quality anodes that will effectively inhibit corrosion when used in a properly designed and maintained cathodic protection system. NeoCast's magnesium anodes conform in composition to the requirements of European Union standards. This 6% aluminum, 3% zinc alloy (AZ-63) usually provides the best combination of economy and operating characteristics in seawater or brackish water. For further information, or to discuss your specific requirements, contact our sales office.

Head forms according to the European standard EN 960:2006

We are proud to announce that NeoCast is now in a position to supply you with a set of magnesium alloy headforms (all standard sizes available, see Fig. 1) that fully comply with all the requirements of the current EN960:2006 standard in terms of shape, precision-balanced centre of gravity and high resonance frequency. The optimal properties of our headforms are the fruit of a major research commitment and the use of new technologies throughout the entire production cycle. In the design stage, we use state-of-the-art CAD programs to create digital schematics enabling us to include all the technical parameters to be taken into account in the production of the desired headforms.

We are proud to announce that NeoCast is now in a position to supply you with a set of magnesium alloy headforms (all standard sizes available, see Fig. 1) that fully comply with all the requirements of the current EN960:2006 standard in terms of shape, precision-balanced centre of gravity and high resonance frequency. The optimal properties of our headforms are the fruit of a major research commitment and the use of new technologies throughout the entire production cycle. In the design stage, we use state-of-the-art CAD programs to create digital schematics enabling us to include all the technical parameters to be taken into account in the production of the desired headforms.